OPT-SHOES CONCEPT

About 200.000 EU employees are involved in the manufacturing of almost 750 million pairs of casual shoes. About 1-2% of shoes are turned back by the customers due to qualitative problems related to the comfortableness and functionality of their purchased product. Discomfort, pain and numerous foot problems are directly connected to the shoes functionality. Previous studies (Meshi, 1998) have shown that over 75% of the population in the western civilization have moderate-to-severe foot problems. These foot problems cost to the US economy, for example, about $3.5 Billion/year. Another survey (Christensen, 2000) of 620 women established that the majority was dissatisfied with their shoes because they hurt their feet, even though most had paid between $50 and $200 per pair. Not surprisingly, women have about 90 percent of the nearly 800,000 annual surgeries for neuromas, bunions and “hammer toes”.

The most frequent and serious shoe-related issues are musculoskeletal disorders and fatigue affecting lower-limb and back, skin damage and slips-and-falls. As a consequence, workers suffer discomfort, which is the main cause for not wearing their prescribed shoes and reduces attention and performance at work (Bishu & Goonetilleke, 1998; Pabon-Gonzalez, 2001). These health & discomfort problems are caused by the lack of biomechanical and physiological functionality of footwear beyond the compliance with standards. The total health care and sick leave costs for these problems that can be directly attributed to footwear are estimated at €1.8 Bn to National Health Systems and employers.

This research proposal focuses on the development of cost-effective and accurate computer-aided design and engineering (CAD/CAE) tools for the determination and optimization of design parameters used for the development of comfort casual and professional footwear. In particular, this 36-months research will deliver novel CAD/CAE tools for determining and optimizing the following footwear-related functionalities: (1) fitting, (2) shock absorption, (3) foot plant pressure distribution, (4) bending/torsion. The determination and optimization of these parameters necessitates the development of (a) highly-accurate foot and shoe models, (b) appropriate finite-element models of the foot and shoe components, and (c) highly-accurate simulation tools based on human behavioral models for performing FEA in order to determine and optimize footwear parameters related to comfort.

Despite its significant scientific merits the proposed project will provide important technological benefits to the footwear manufacturing sector by accomplishing the following technological objectives (TOs):

- TO1: Generation of algorithms for 3D foot biomechanics data processing, segmenting and modeling.

- TO2: Implementation of software modules for evaluating and optimizing design parameters related to the footwear functionality.

- TO3: Generation of 3D foot models for simulating the foot-footwear interaction.

- TO4: Availability of the complete solution as a service in a Cloud-Computing Environment.

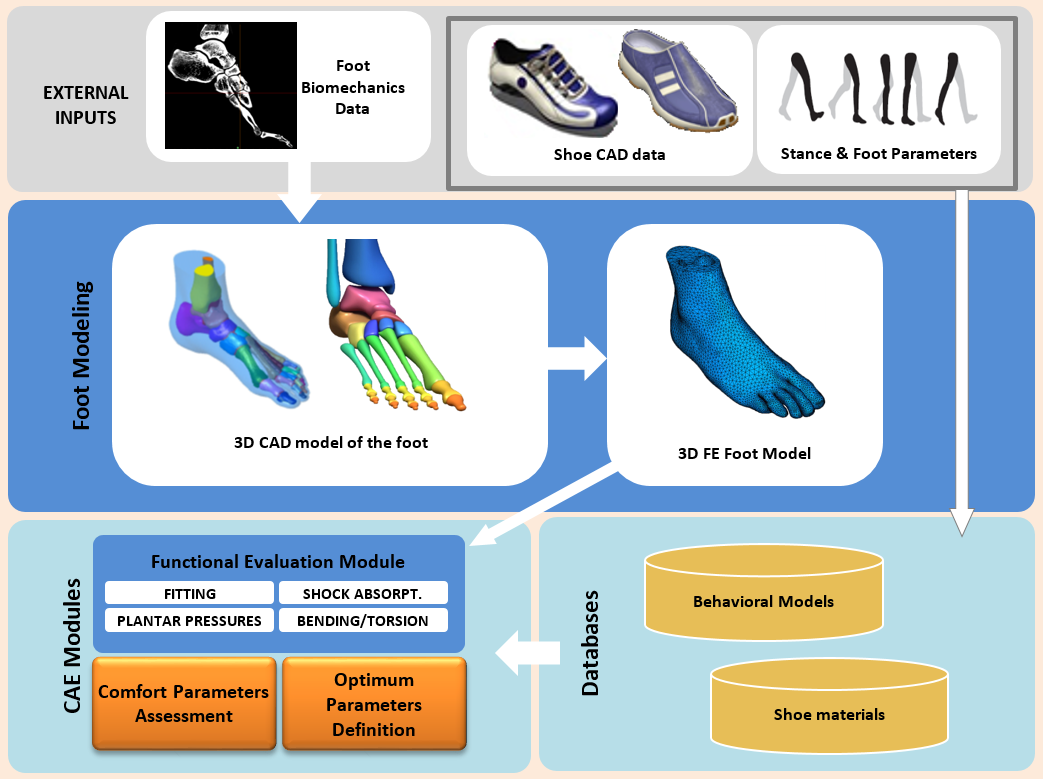

The final system will enable footwear manufacturers to produce high-quality casual or professional shoes complying with the necessary comfort standards. A unique characteristic of the proposed solution is that it will be available either for mass production or for manufacturing customized products. The latter case ranges from high-performance shoes for athletes to individual orthopedic shoes. A schematic view of the final technological solution is depicted in Fig.1. The system is composed of four parts: (1) External inputs: a software layer for introducing foot and shoe data. (2) Parametric feature-based foot modeling: this module will enable the development of accurate 3D foot models which in term will allow the derivation of accurate 3D FEM models of the foot. (3) Databases: Two major databases will be developed. One for holding various shoe materials and their relative properties, and one for the behavioral models. Both databases will be used in the FE analysis. (4) CAE modules: the actual computations will be performed in this layer using appropriate FEA software. The outcome of these computations will be used to assess and optimize the requested comfort parameters. It must be noted that the entire solution will be available in the Cloud.